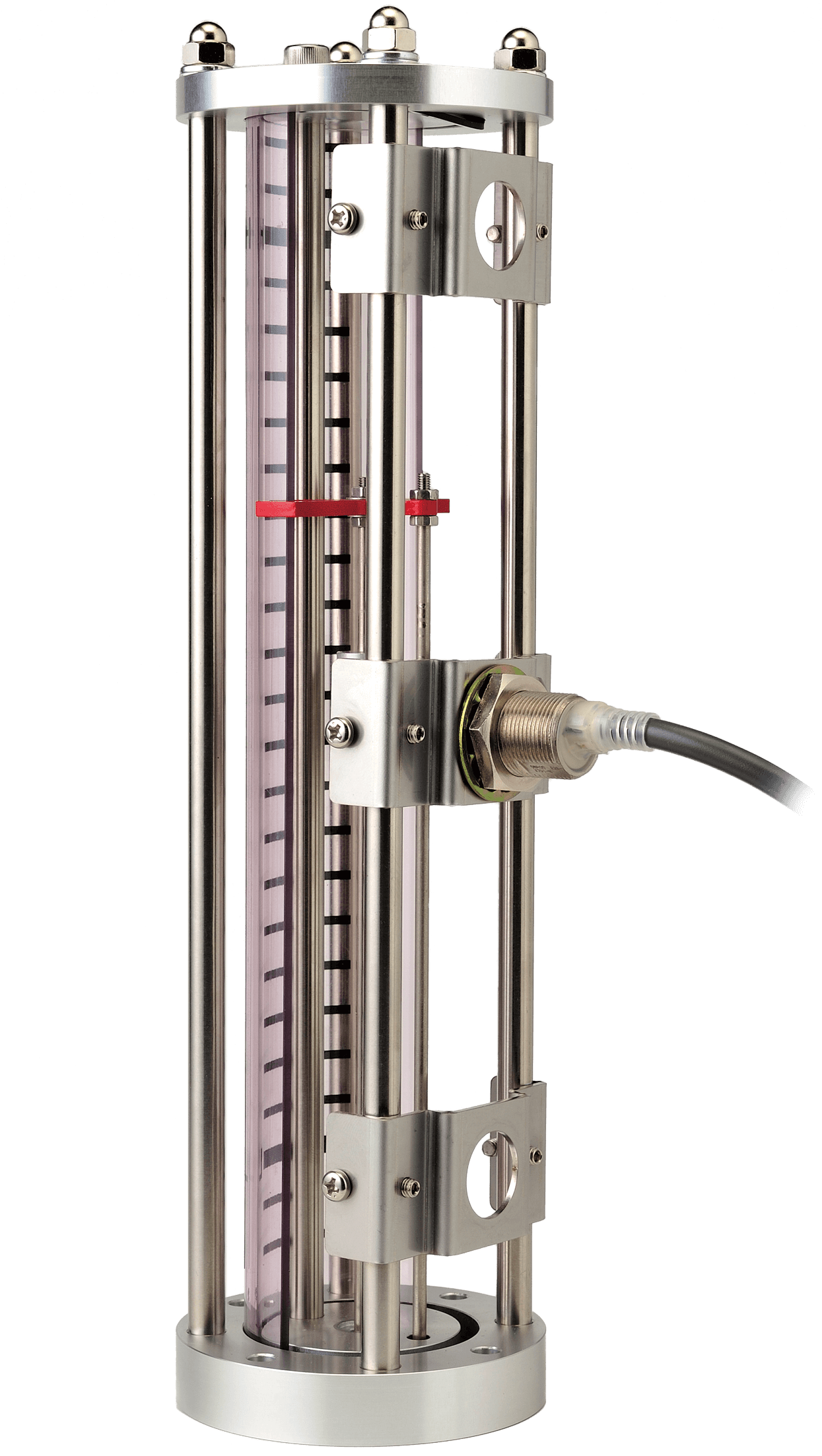

- Pursuing “robustness” and “durability”, with uncompromised excellent “visibility”, the electric control friendliness is additionally achieved.

- Without sacrificing durability of the conventional Clean Level Towers, the continuous detection type that is designed to be attached to the top surface of the tank allows significant visibility and easier electronic monitoring.

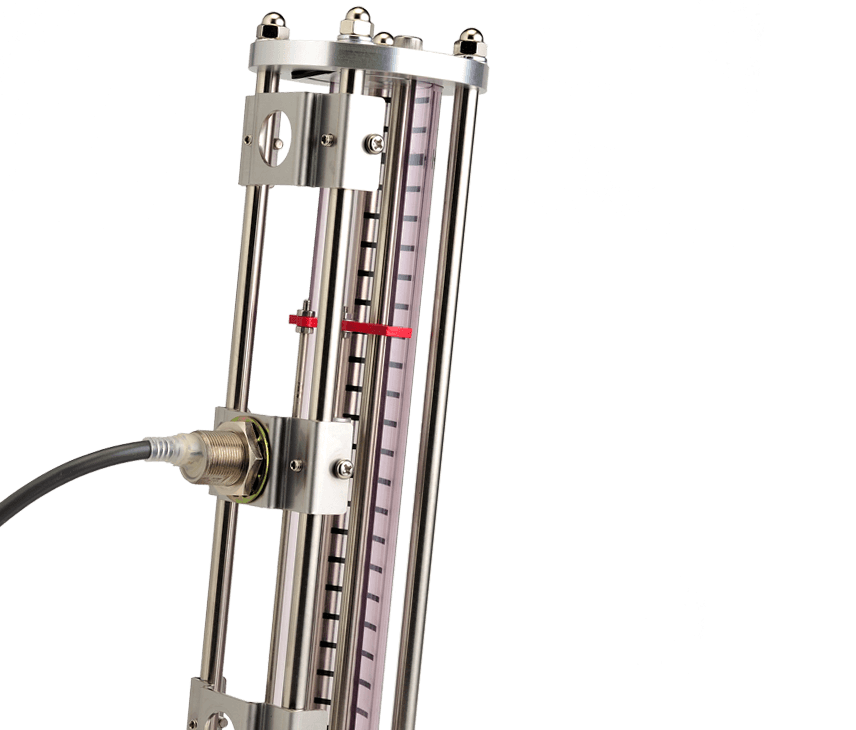

- The detector specifications characterized by the continuous liquid level monitoring

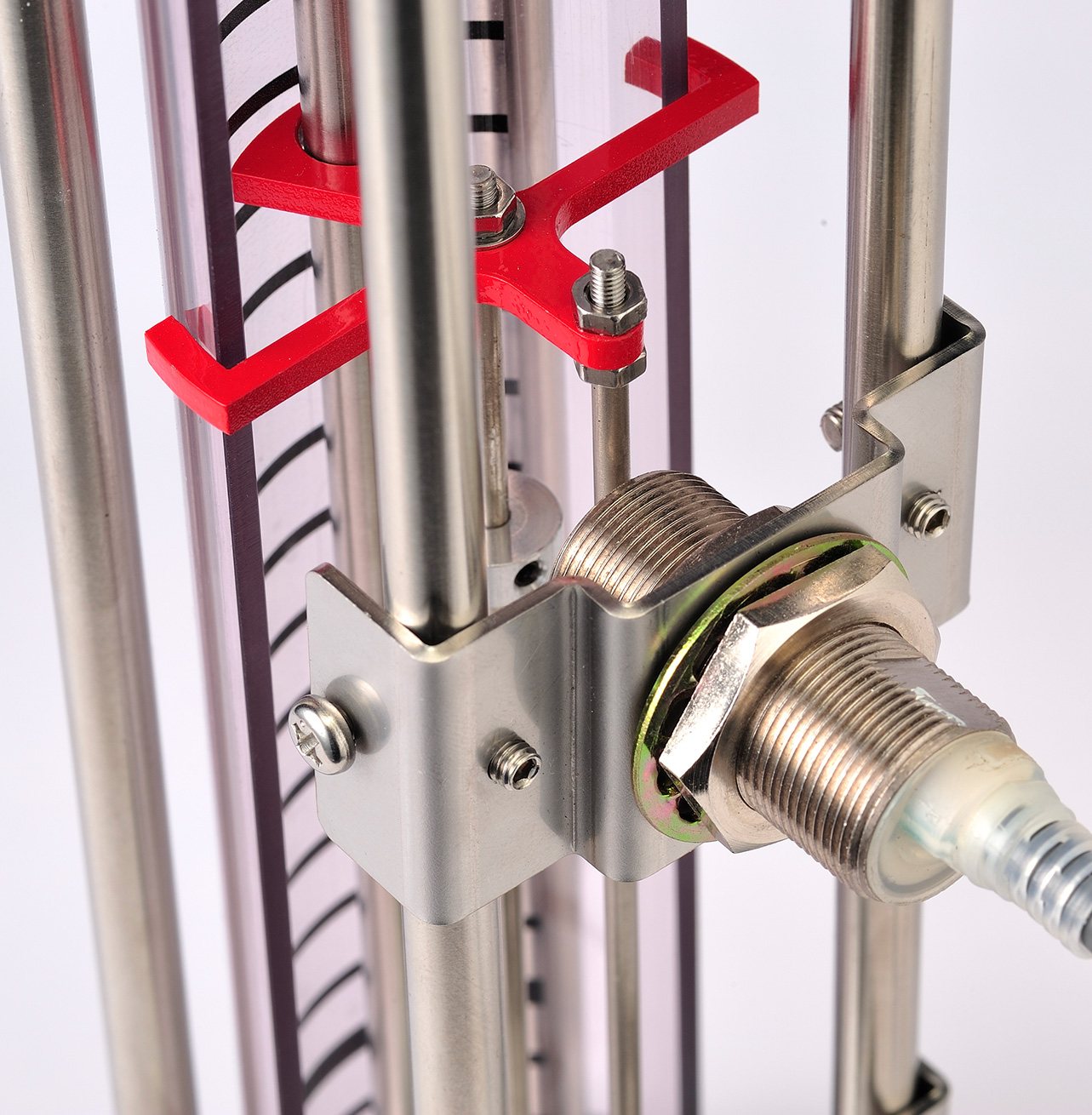

- Without changing the lower limit and lower limit alarms use cases for predictable detection, the liquid level can be continuously monitored and controlled. Moreover, installation of the sensors (auto/proximity switching) is quite easy, effectively helping the central level control.

FEATURE

Key Features of Clean Level Tower

-

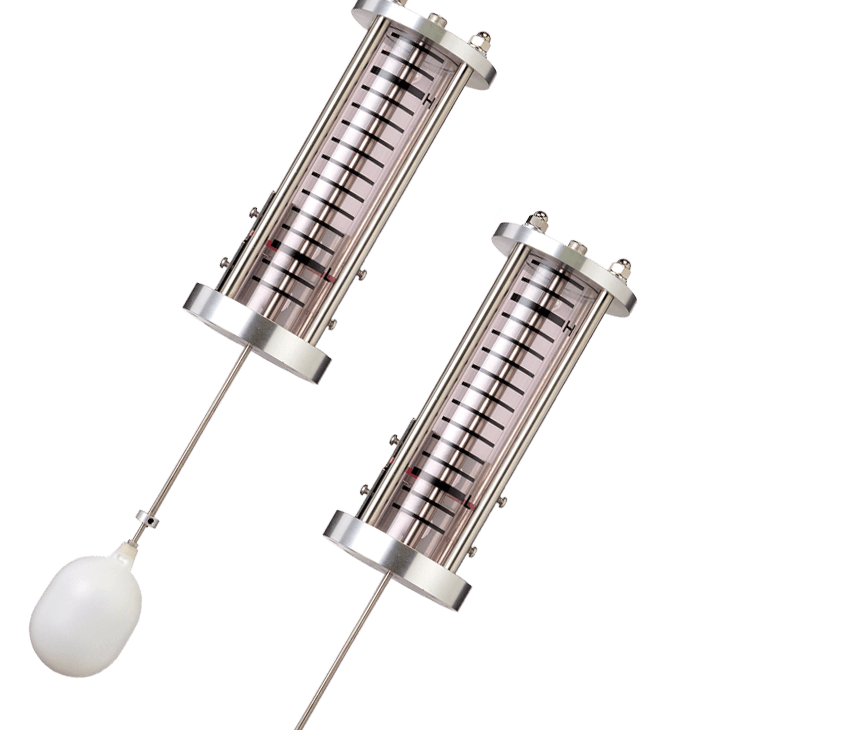

- For coolants

- With the enhanced oil and chemical resistance specifications, it can be used for different cutting oils.

- 01

-

- For cleaners/scrubbers

- The float made of SUS316 is used. Good for heated cleaners/scrubbers.

- 02

-

- For extra high buoyancy

- Best used in case the required buoyancy cannot be obtained with the regular float.

- 03

DOWNLOAD

Drawings and brochures download

- Koike’s Aluminum Flange Type Level Gauges

(KOIKE LEVEL GAUGE) - Click the button below to view the material. Adobe Acrobat Reader is required to view pdf files. Adobe Acrobat Reader is available for free from Adobe. Click here to download the free Reader.

- DOWNLOAD

SPEC

Specifications

- Made-to-order

- The Clean Level Towers are all made to order. We will propose the best-suited product to our customers’ requirements in accordance with the specifications. Contact us now and let us be of the best help to you.

- Air Breezer Function

- Thanks to the Air Breezer function available in the Clean Level Towers (CLT variants), the hot air and vapor inside the tank will be dumped outside (except for the CLT variants for coolants and for cleaners/scrubbers as well as CLG variants). For hydraulic tanks, this feature works well for prevention of rusting inside the tank as the moisture will hardly remain there.

- Float structure

- Inside the tank, the structure only contains the float. As the detector block is installed on the top surface of the tank, such problems as switching errors caused by sludge of some magnetic substance will be eliminated.

- Options

(representative ones) -

Measurement target Hydraulic oils, coolants, cleansing fluids, lubricants Switching type auto/proximity switching Switching measurement position Detection of upper, lower, upper + lower, and multiple limits Float material Polypropylene/stainless-steel H – L dimension Special orders for customization (in 5mm orders) in accordance with the tank size/shape are acceptable. Nominal length Special orders for customization (in 5mm orders) in accordance with the tank size/shape are acceptable.

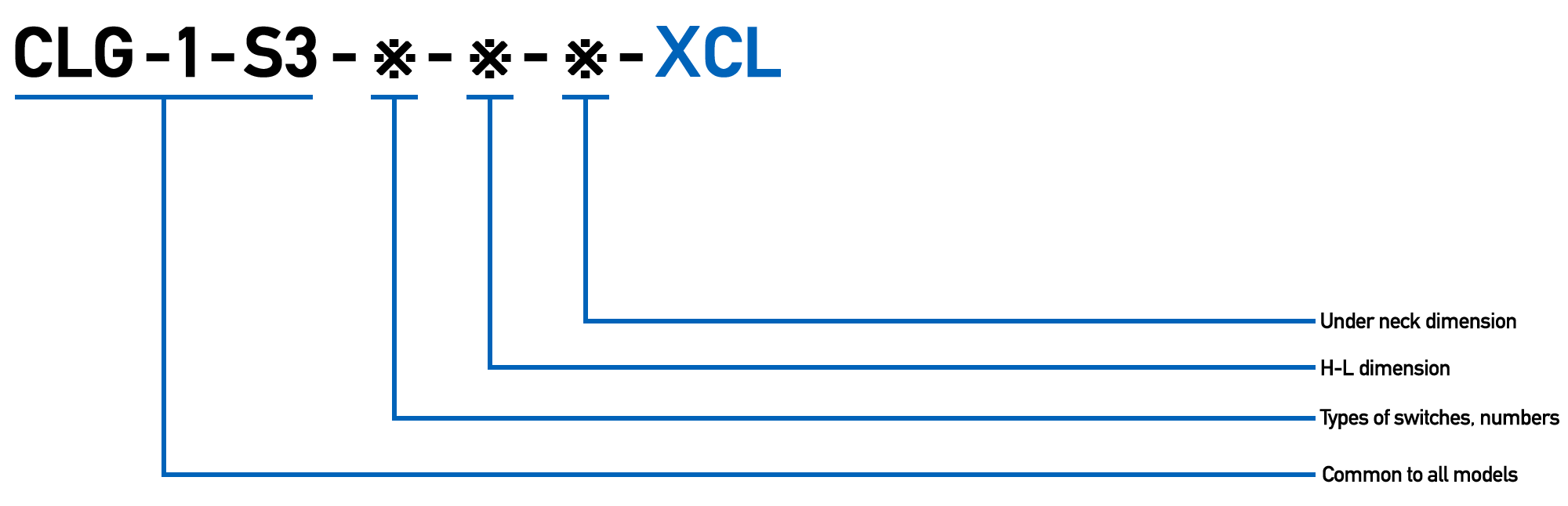

- Product code convention

(Coolant tank code/extra high buoyancy)

Coolant tank code (extra high buoyancy) CLG-1-S3-※-※-※-XCL Coolant tank code CLG-1-S3-※-※-※-XC Cleaner/scrubber tank code CLG-1-S3-※-※-※-XS

- The Air Breezer function is limited to the CLT variants for hydraulic oils.

- The level gauges can be customized in 5mm orders.

- The float size can be larger depending on the dimensions. Please pay attention to the dimensions for deeper tanks.

(PP float H – L dimension + nominal length is 500mm or greater GL or CL)

(SUS float H – L dimension + nominal length is 800mm or greater SL) - To install multiple switches, please install them at 40mm intervals. As the customization to make the intervals smaller is available, contact us if necessary.

- The switch lead lengths are 3m for auto switching and 2m for proximity switching. An optional 5m lead is also available.

- For CLT variants, attaching the protection cover to prevent breakage is recommended. (The cover is attached as standard for proximity switching types.)

- Check the switch specifications on the drawings.